Economical production of metallic bipolar plates

Project ”BPP coating”

Challenge

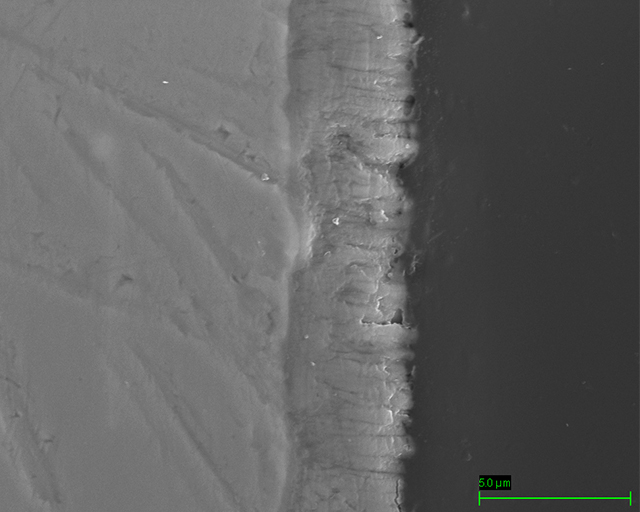

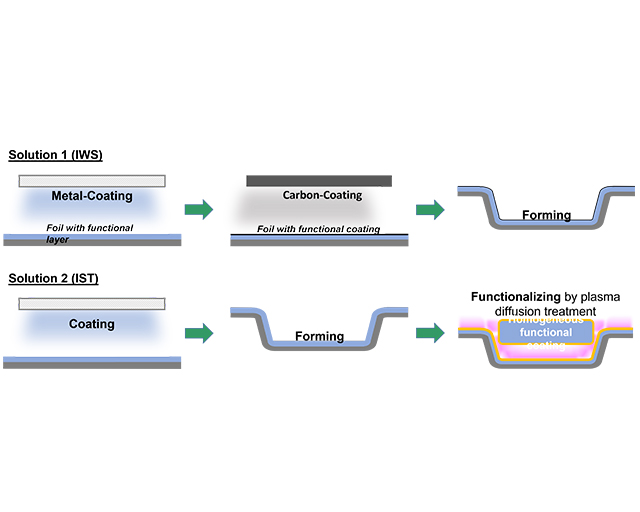

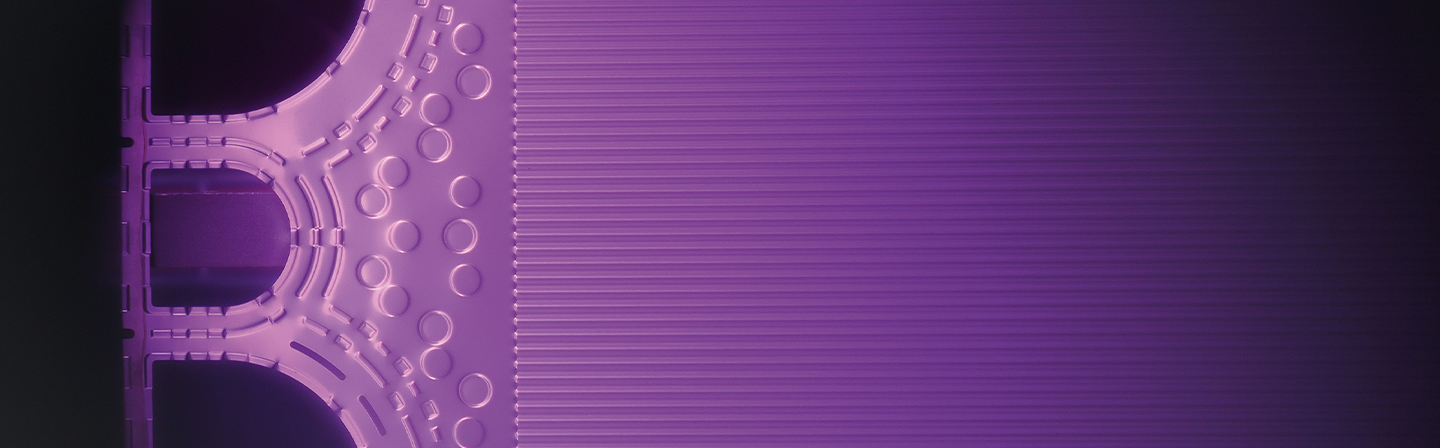

The application of PEM fuel cells (polymer electrolyte membrane fuel cells) offers promising prospects for stationary energy generation, electromobility and the reduction in dependence on fossil fuels; it is, however, currently limited by cost-intensive large-scale production. The bipolar plate (BPP) is one of the most cost-intensive components in the PEM fuel cell. As a result of its operating conditions, it is subject to high demands in terms of electrical conductivity and corrosion resistance. The “BPP coating” project is focused on improving these properties, increasing the service life, and enabling economical production through the development and testing of new production methods for metallic BPPs. Within the framework of the project, two different solution approaches are being pursued, each of which combines different coating and shaping processes such as embossing or hydroforming.

Solution

The Fraunhofer IST solution approach is based on metallic foils coated with titanium, which are functionalized through plasma diffusion treatment following forming. As a result, the defects caused by forming should be minimized and, at the same time, corrosion resistance should be improved.

Added value

The performance capability of the differing approaches is being investigated in various forming processes. The aim is the development of a cost-effective, efficient and scalable production process for BPPs. In this way, the production of key components for the utilization of green hydrogen is to be developed, thereby providing a contribution towards the energy transition in Germany and Europe.