Extreme lightweight construction in aerospace: Metallized CFRP

Challenge

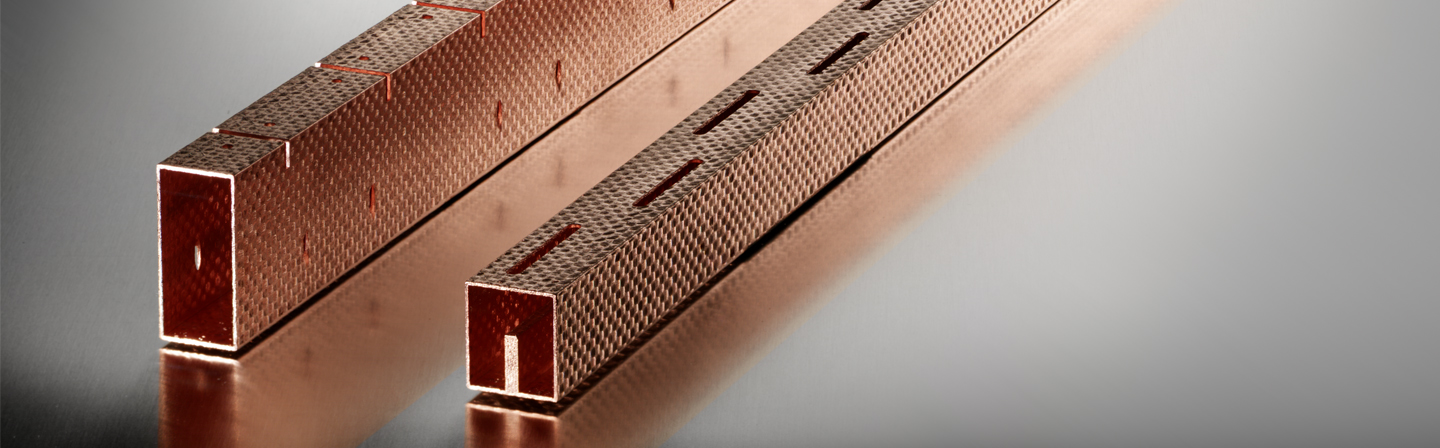

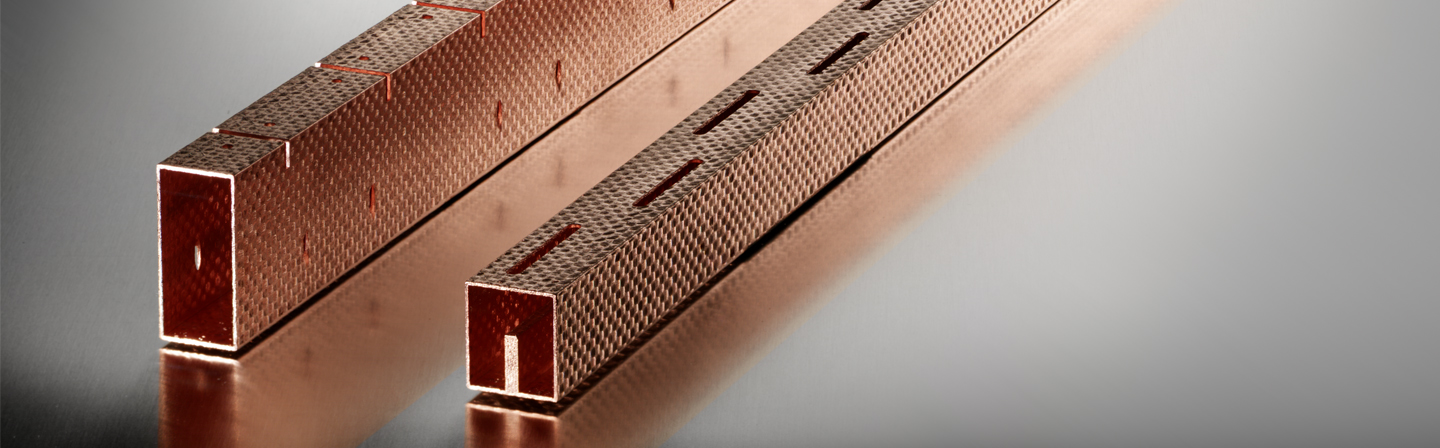

The starting situation was that CFRP waveguides in this dimension (l~ 95 cm, d ~ 3 cm) were to be metallized without defects for the first time. In addition to the dimension, the challenges were the complex geometry (internal coating) and the assurance of the adhesion of the layer under strongly fluctuating temperatures. The goal was the copper-plating of waveguides as flight articles for 4 satellites (approx. 5000 pieces).

Solution

On a laboratory scale, the process parameters (pickling, pre-metallizing, metallizing) were adjusted on test specimens in such a way that the requirements for roughness, freedom from defects and uniformity were fulfilled. Subsequently, the technical equipment was constructed and the parameters were adapted to the modified requirements of the technical operation (operational reliability, economy). The process reliability was verified on original components. The adhesion mechanism as well as the coating thickness were continuously ensured and documented by means of microscopy on transverse sections.

Added value

The result was the complete realization of the waveguide as a flight article (TRL 9). Two of the four satellites of the Sentinel 1 program are already in orbit. As a result of the expertise thereby gained, further projects such as DLR-MASCOT and DLR OCULUS were acquired. This process will be used in the future in order to combine the advantages of CFRP (low weight, high strength) with those of metals (electrical conductivity).