Surface technology and pharmaceutical process engineering – What is the Fraunhofer IST working on in collaboration with the PVZ at the TU Braunschweig?

In pharmaceutical production, the interaction of particles with surfaces plays a decisive role. Whether these particles – either in the form of active ingredients or granules – adhere or are easily detached depends on the properties of the surfaces involved. Depending on the product and process, the specific requirements for the production and subsequent application of various medicinal products can vary: For example, strong adhesion can be important in the formulation of stable dosage forms, whereas in other cases the prevention of deposits is crucial in order to avoid expensive cleaning steps.

Today we are talking to Dr. Kristina Lachmann, Head of Medical Technology and Pharmaceutical Systems at the Fraunhofer IST, and Dr. Jan Henrik Finke, a staff member at the Fraunhofer IST and Head of the “Pharmaceutical and Bioparticle Technology” department of the Institute for Particle Technology iPAT at the Center of Pharmaceutical Engineering (PVZ) at the TU Braunschweig, regarding the application of surface technologies in pharmaceutical production. With the help of examples, they will provide us with insights into how manufacturing processes can be optimized by means of innovative coatings.

Dear Kristina, dear Jan, in which areas of the production process for medicinal products does surface technology play a role?

Kristina: Surface technology is important in almost all steps of medicinal-product manufacture – from the synthesis of the active agent, through the production of the dosage form, and on to packaging and the patients’ use of the product. This means that the interaction of pharmaceutical particles with surfaces – with which they inevitably come into contact during their synthesis, formulation or utilization – must be precisely characterized and adjusted by means of surface technology. At the Fraunhofer IST, we are working with our partners on all the aforementioned points of the process chain and can offer comprehensive services in this regard: from consultancy, through characterization, on to coating development, and testing in industry-relevant processes at the PVZ. One example is tableting processes: In the field of coatings for tablet presses, we have acquired extensive experience through many years of cooperation with the pharmaceutical industry.

Surface technology can therefore be used to adjust the adhesion properties. Can you explain this to us in more detail using the example of tablet presses?

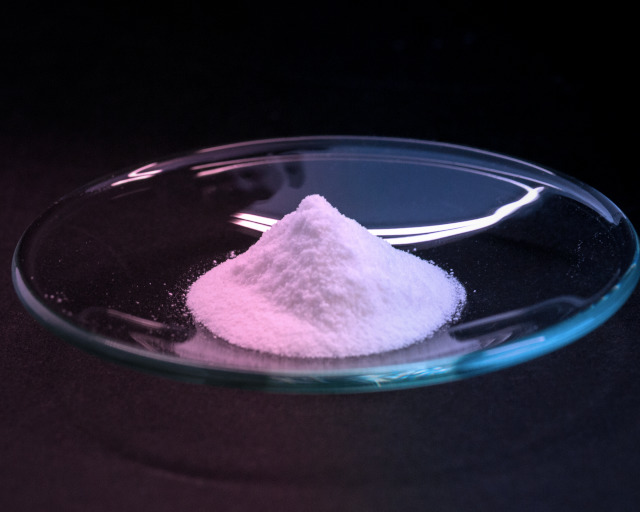

Jan: For the production of tablets, the active ingredient is usually initially available as a powder and must be pressed into shape using tablet presses, for example. It is thereby particularly important that “sticking” (an undesired adhesion of the powder to the punches of the press) does not occur, as this leads to machine downtimes, higher cleaning costs and losses in product yield. Additionally – and substantially more critical for the patient – is, however, the fact that the dosage may no longer be correct. In particular, new active ingredients often present a special challenge when it comes to establishing the correct dosage in the end product, i.e. in the tablet. A team from the Fraunhofer IST is currently working on enhancing the scientific understanding of particle-surface interaction. The aim is to offer customized surface coatings for the presses with which the interaction forces can be specifically controlled in order to directly improve the efficiency and stability of the production processes.

In addition to the control of the adhesion, which is controlled by the physicochemical properties of the coating, further surface properties – e.g., a certain wear resistance – are often required depending on the product and process. These can also be specifically adjusted by means of the coating systems, technologies and expertise available at the Fraunhofer IST.

The project for controlling adhesion in the tableting process is an example of the cooperation between the Fraunhofer IST and the Center of Pharmaceutical Engineering (PVZ) at the TU Braunschweig – but who actually does what?

Kristina: At the Fraunhofer IST, we have acquired extensive expertise in the deposition of thin wear-resistant coatings and have been working with various manufacturers from the pharmaceutical industry for many years. The cooperation with the PVZ enables us to examine our coatings within an industry-relevant infrastructure and to systematically develop them further, in order to be able to offer the best solution for the respective application. At the Fraunhofer IST, we concentrate on the coatings, further developing existing coating systems, or utilizing completely new material systems. We thereby also focus on the industrial feasibility of the process and on the characterization of the coating properties – both in dependence on the process conditions of the coating deposition and also for the application within the pharmaceutical process chain.

Jan: At the Center of Pharmaceutical Engineering, we have – as the name directly suggests – the infrastructure and the knowledge required to analyze pharmaceutical processes such as the production of active ingredients and dosage forms. Our collaboration with the Fraunhofer IST perfectly complements this, as we are able to test coated surfaces under real production conditions. This results in an intense interaction between materials science and process development, which offers new, practical solutions for industry.

What results have you already achieved?

Jan: Our knowledge regarding adhesion control in the tableting process can be transferred to other processes. We are currently also working with industry partners on the milling of active ingredient particles and technologies for capsule filling. In a further project on inhalation therapy, we were able to demonstrate that our coatings reduce the particle deposition on the surface of the inhalers by up to 80 %. This significantly increases the utilization safety of the medical products and the effective use of the active ingredient dosages.

What do you hope for as regards the successful continuation of the collaboration?

Kristina: We have lots more ideas for future projects or topics that we want to explore and improve with the help of surface technology. From a strategic perspective, it is important for us that the knowledge we have gained through fundamental research is transferred into relevant solutions for the application. The TU Braunschweig is an important strategic partner in this endeavor.

In the process steps mentioned so far, primarily tools from the process chain are being modified. The coatings can, however, be applied just as effectively and directly to a wide variety of medical products, for example to the aforementioned inhalers made from plastics. Again, the interactions between the medication and the surface must be adapted to one another in such a way that losses during administration by the patient can be avoided.

A further field of research is the investigation of interactions with the packaging or a possible modification of the pharmaceutical particles themselves. In the current joint project “RNApp”, which is being funded by the State of Lower Saxony, the Fraunhofer IST is therefore investigating the interactions of mRNA-containing lipid nanoparticles with the packaging. The aim is to reduce these interactions in order to increase the storage stability. The project offers us the possibility of expanding our cooperation with the TU Braunschweig and, furthermore, of opening up a further field of research that perfectly complements the expertise of the PVZ.

Jan: One topic that has not yet been discussed is the 3D printing of medicinal dosage forms. Our aim here is to combine the expertise of two institutes: As regards the Institute for Particle Technology iPAT at the TU Braunschweig, this means the field of manufacturing and characterizing active-ingredient-containing intermediates – in this case filaments – as well as release control in dosage forms, and for the Fraunhofer IST, the field of improving adhesion in material combinations and the introduction of functional layers for release control. This is a further exciting perspective for future projects.

Last modified: